Rims are more than just a stylish addition to a vehicle; they are integral to its performance. Their influence extends to acceleration, braking, and handling, making them a crucial consideration for both casual drivers and performance enthusiasts.

The weight and material of rims significantly impact a vehicle’s acceleration and braking. Heavier rims add rotational mass, requiring more power to move the wheels, leading to slower acceleration. Conversely, lighter rims reduce inertia, allowing quicker acceleration and shorter braking distances. Handling is also affected, as a lower rim weight improves response time and maneuverability, particularly in tight turns and high-speed conditions.

The right rim choice depends on the terrain and driving habits. Performance cars benefit from lightweight alloy or carbon fiber rims for enhanced speed and control. In contrast, off-road vehicles require durable steel rims that can withstand rough conditions. Urban commuters might prioritize fuel efficiency and comfort, making mid-weight alloy rims an ideal choice.

The Science Behind Rim Design

Rim design isn’t just about aesthetics; it’s a product of engineering and physics. Every curve, material, and structural component plays a role in how a vehicle interacts with the road.

Rims must balance strength and weight while maintaining structural integrity. Engineers use computer-aided design (CAD) simulations to optimize rim shape for aerodynamics, ensuring minimal resistance while driving. The spoke pattern, lip depth, and hub placement all contribute to performance.

Rotational mass, or the weight of moving components, directly affects how a car behaves on the road. Heavier rims increase the effort required to accelerate and stop, whereas lighter rims reduce this effort, leading to better fuel efficiency and smoother handling. This concept is particularly important in motorsports, where every millisecond counts.

Materials Matter

Choosing the right rim material can make or break a car’s performance and durability. Each type offers distinct advantages and drawbacks.

- Steel Rims. Steel rims are known for their durability and affordability. They are ideal for rugged conditions and winter driving due to their resistance to impact damage. However, their heavier weight can negatively affect acceleration and fuel efficiency.

- Alloy Rims. Alloy rims, typically made of aluminum or magnesium, offer a middle ground between performance and durability. They are lighter than steel, improving fuel efficiency and handling, and are also more resistant to corrosion. However, they can be more expensive and prone to bending under extreme force.

- Carbon Fiber Rims. For high-performance vehicles, carbon fiber rims provide an unparalleled strength-to-weight ratio. These rims reduce unsprung weight, improving acceleration and responsiveness. However, their high cost and vulnerability to impact damage make them less practical for everyday use.

Rim Size

Size matters when it comes to rims. The right diameter affects ride comfort, fuel efficiency, and handling.

Larger rims can improve handling by providing a wider contact patch with the road. However, they also make for a stiffer ride due to lower-profile tires and increased rolling resistance. Smaller rims, on the other hand, offer a more cushioned ride and better fuel economy.

While larger rims enhance cornering stability and grip, they also transmit more road imperfections into the cabin. This trade-off is important to consider for those seeking both performance and comfort.

Smaller rims allow for higher-profile tires, which absorb road bumps better, making them ideal for city driving. Off-road enthusiasts also benefit from smaller rims with thicker tires that provide better traction and shock absorption.

Rim Width

Rim width is a critical factor that determines how a vehicle interacts with the road surface. A properly selected rim width can enhance traction, cornering stability, and even fuel efficiency. However, the choice between wider and narrower rims involves trade-offs that impact performance and driving comfort.

Wider rims provide a larger contact patch, allowing for increased road grip and better cornering ability. This is particularly beneficial for performance vehicles that require high levels of stability at high speeds. With a broader tire footprint, there is reduced rolling movement, leading to more predictable handling and reduced risk of understeer or oversteer in aggressive driving situations. Additionally, wider rims improve braking performance as the tires can distribute stopping force more effectively. However, they also introduce greater rolling resistance, which can slightly reduce fuel efficiency.

Narrow rims are commonly used in vehicles designed for fuel efficiency and daily commuting. Their reduced width minimizes rolling resistance, allowing the vehicle to move with less effort and consume less fuel. They also allow for higher-profile tires, which absorb road imperfections better, leading to a more comfortable ride. While narrower rims do not provide the same level of cornering grip as wider ones, they are ideal for highway driving, where stability and efficiency take precedence over aggressive handling.

Choosing the ideal rim width depends on the type of driving you do. Performance-oriented drivers may prioritize wider rims for superior traction and stability, while those focused on fuel economy and comfort might opt for narrower ones. Understanding these trade-offs allows for an informed decision that aligns with both functional and aesthetic goals.

The Weight Factor

Rim weight is a crucial factor in overall vehicle performance. Heavier rims increase the rotational mass, which means more effort is required to accelerate and decelerate. This added weight can affect steering responsiveness and fuel efficiency. On the other hand, lightweight rims contribute to a more agile driving experience, reducing strain on the suspension system and improving fuel economy. Understanding how rim weight interacts with vehicle dynamics can help drivers make informed choices when selecting wheels.

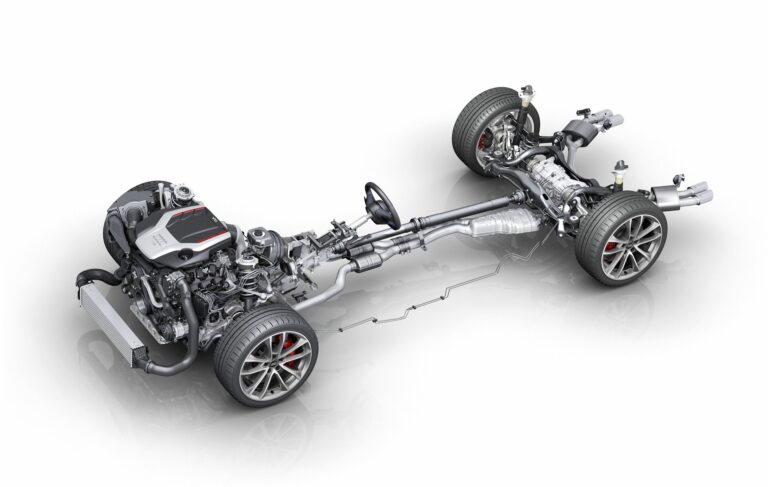

Unsprung weight refers to components of the vehicle that are not supported by the suspension, including wheels, tires, and brakes. Reducing unsprung weight is critical for enhancing acceleration and improving ride quality. Heavier rims add to the vehicle’s unsprung mass, making it harder for the suspension to react to road imperfections. This can lead to reduced handling precision and increased wear on suspension components. In contrast, lighter rims reduce inertia, allowing for quicker throttle response and better weight distribution.

Switching to lightweight rims can significantly improve handling, as they allow for sharper turns and reduced body roll. Lighter wheels also reduce the overall load on the drivetrain, improving fuel efficiency by requiring less power to rotate. Performance vehicles and sports cars often utilize lightweight alloy or carbon fiber rims for maximum speed and agility. However, it’s essential to strike a balance—extremely light rims may compromise durability and structural integrity, particularly on rough roads. Drivers must consider their specific needs, whether prioritizing efficiency, performance, or longevity when selecting the ideal rim weight.

Spokes and Speed

Spokes are not just decorative elements; they serve a crucial structural and functional purpose. The number, shape, and arrangement of spokes influence a wheel’s weight, strength, aerodynamics, and cooling efficiency. A well-designed spoke pattern can enhance vehicle performance by optimizing airflow, reducing drag, and maintaining structural integrity under stress.

Braking generates substantial heat, and improper heat dissipation can lead to brake fade, reducing stopping power. Open-spoke designs allow for greater airflow around the brake components, helping to keep them cool and functional during intense driving conditions. Performance-oriented vehicles, such as sports cars and race cars, often incorporate open-spoke rims for this reason.

Closed-spoke or solid-disc designs, on the other hand, limit airflow but improve aerodynamics by reducing turbulence. These rims are often found on fuel-efficient and electric vehicles, where reducing drag is prioritized over heat dissipation. While they may not cool brakes as efficiently, their smooth surfaces help enhance fuel economy and extend driving range.

The number of spokes in a wheel plays a significant role in its overall performance. More spokes provide better weight distribution, increasing structural integrity and durability. This design is preferred for larger vehicles, such as SUVs and trucks, where additional support is needed to handle heavier loads. However, additional spokes also add weight, which can slightly reduce acceleration and handling precision.

Fewer spokes result in a lighter wheel, reducing rotational mass and improving acceleration. This is why many high-performance and track-focused cars feature minimal-spoke designs. However, fewer spokes can also mean less overall strength, making them more prone to bending or damage under extreme conditions. Striking the right balance between weight, strength, and aerodynamic efficiency is key when selecting the best spoke design for a particular vehicle and driving style.

Offset and Backspacing

Wheel offset and backspacing are crucial elements in determining how a wheel sits within the wheel well and interacts with the suspension. These factors influence vehicle handling, stability, and overall aesthetics. A well-balanced offset and backspacing setup ensures that the wheels align properly with the fenders, providing the best combination of performance and visual appeal.

Offset refers to the distance between the wheel’s mounting surface and its centerline. A positive offset means the mounting surface is closer to the outer face of the wheel, pulling the wheel inward. This is common in factory wheels and helps maintain stability and minimize stress on suspension components. A negative offset, on the other hand, moves the wheel outward, creating a more aggressive stance with improved cornering performance but potentially increasing wear on wheel bearings and suspension parts. A zero offset places the mounting surface directly in line with the wheel’s centerline, striking a balance between aesthetic appeal and performance.

Backspacing is the measurement from the wheel’s mounting surface to the back edge of the rim. It determines how much clearance exists between the wheel and suspension components. Excessive backspacing can cause interference with brake calipers, suspension arms, and inner fenders, limiting wheel articulation. Too little backspacing pushes the wheel outward, increasing the vehicle’s track width, which can improve stability but may lead to premature component wear. Finding the right backspacing ensures that wheels fit correctly without compromising handling, safety, or aesthetics.

The ideal offset and backspacing depend on vehicle type and intended use. Performance enthusiasts often opt for lower offsets to widen the stance and improve grip, while daily drivers benefit from factory-recommended specifications to maintain ride comfort and reduce strain on suspension components. Off-road vehicles typically require negative offsets to accommodate larger tires and enhance ground clearance. Understanding these dynamics allows drivers to select wheels that optimize both function and style.